Tobaqos

09 / 2023

idea

Tabaqos is a prototype project from 2016

Introduction

IQOS — also known as Heated Tobacco Products (HTP) — is one of the tobacco industry’s more recent innovations. Instead of burning tobacco, HTP devices heat it to just below the combustion point. The industry markets this as a “healthier” alternative to traditional smoking, claiming it avoids producing tar and other harmful chemicals generated by burning.

To use IQOS, a smoker inserts specially made “heatsticks” — essentially shorter, modified cigarettes — into a heating device. A heated plate warms the stick, releasing nicotine-infused vapor without flame.

The Problem

Legality – Some governments have banned HTP products outright.

Limited Choices – Users must buy proprietary heatsticks, locking them into a single supplier’s tobacco options.

The Proposal – Tobaqos

Back in 2017, I had an idea I called Tobaqos — a reusable cartridge system for IQOS. The concept was similar to refillable Nespresso pods or re-inking printer cartridges. Instead of buying pre-made heatsticks, users could fill the cartridges with loose tobacco of their choice.

Product requirements:

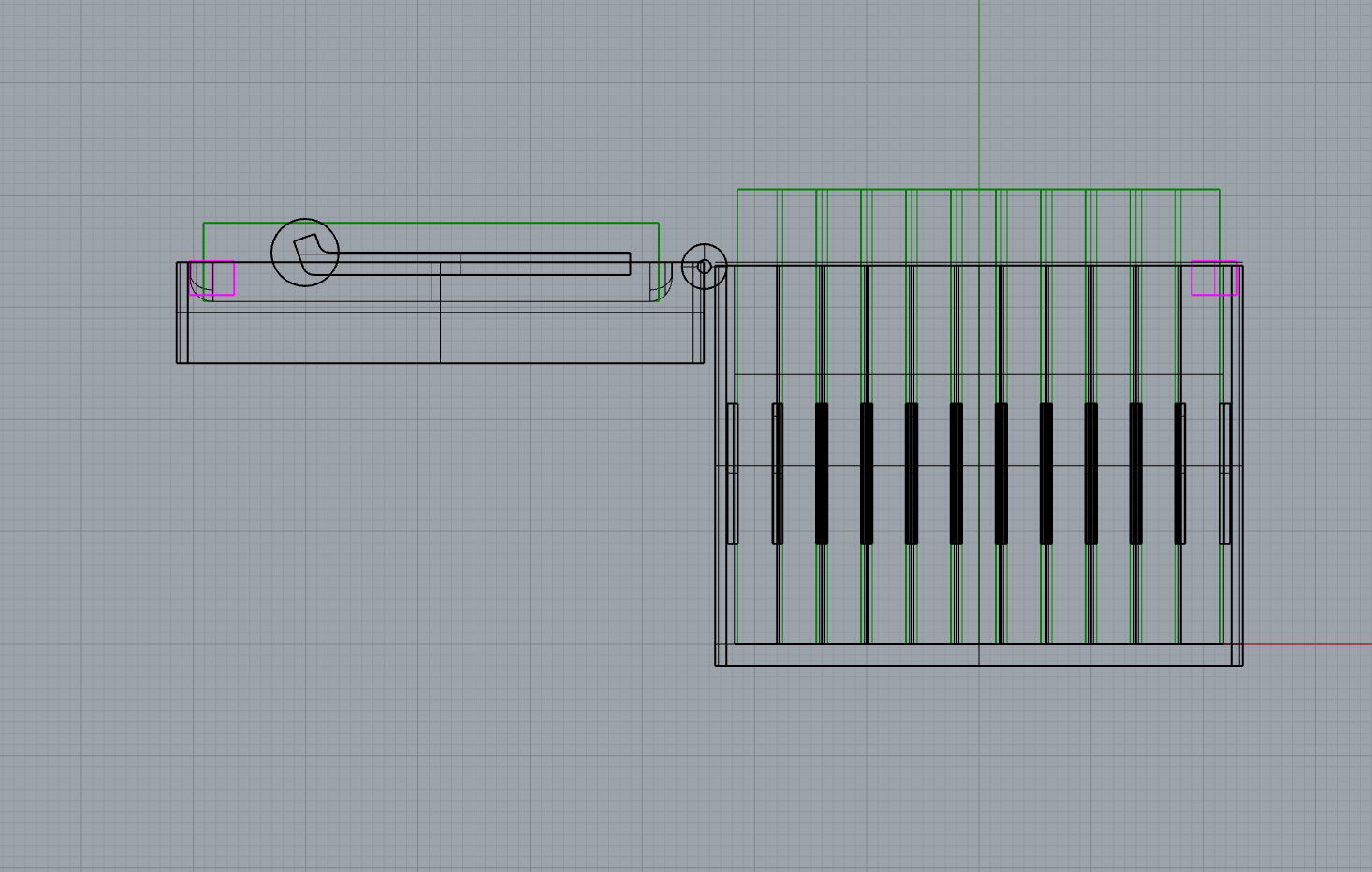

1. Portable and easy to carry.

2. Simple to fill and empty.

3. Easy to clean.

4. Storage for 10 cartridges at a time.

Disassembly & Research

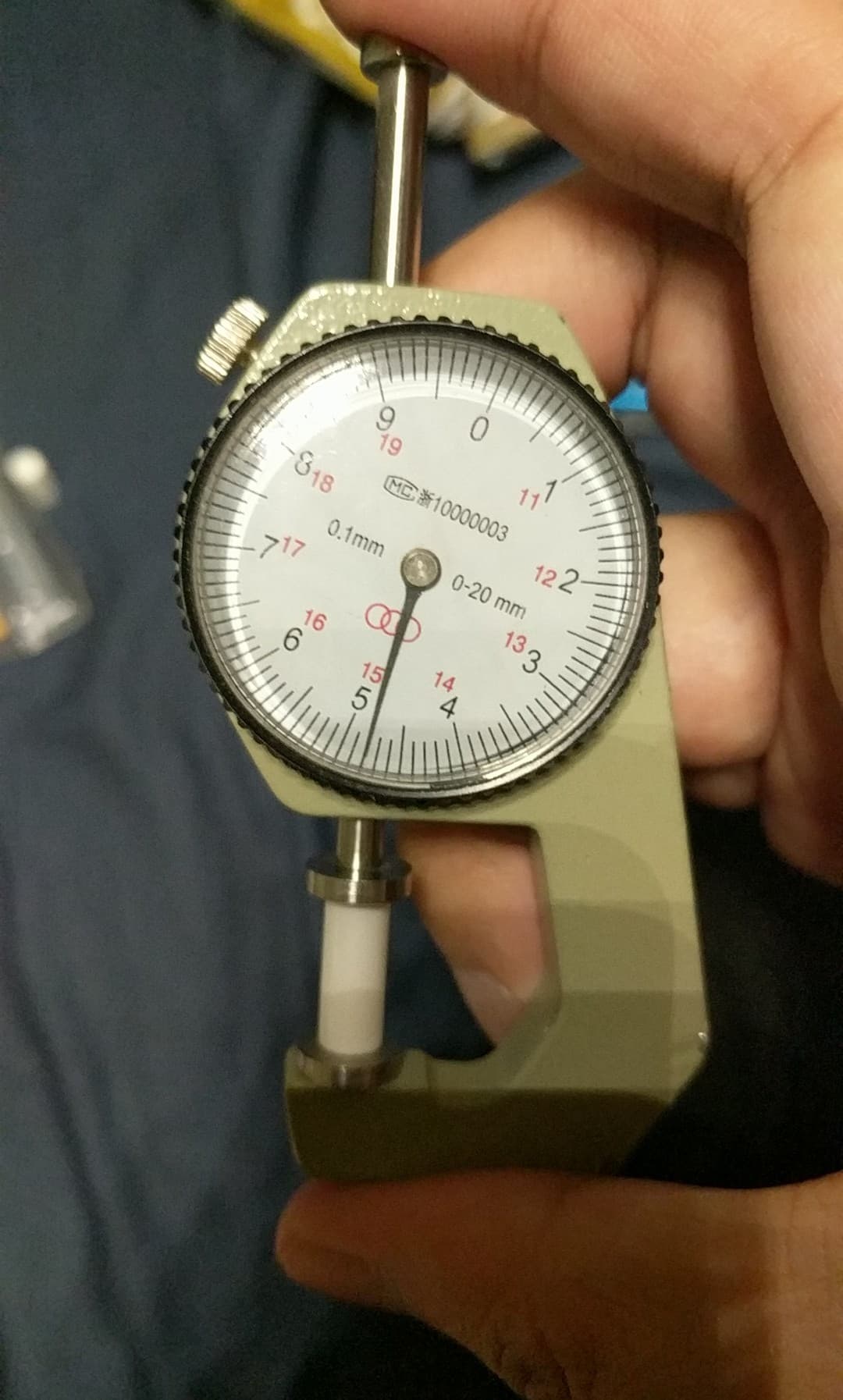

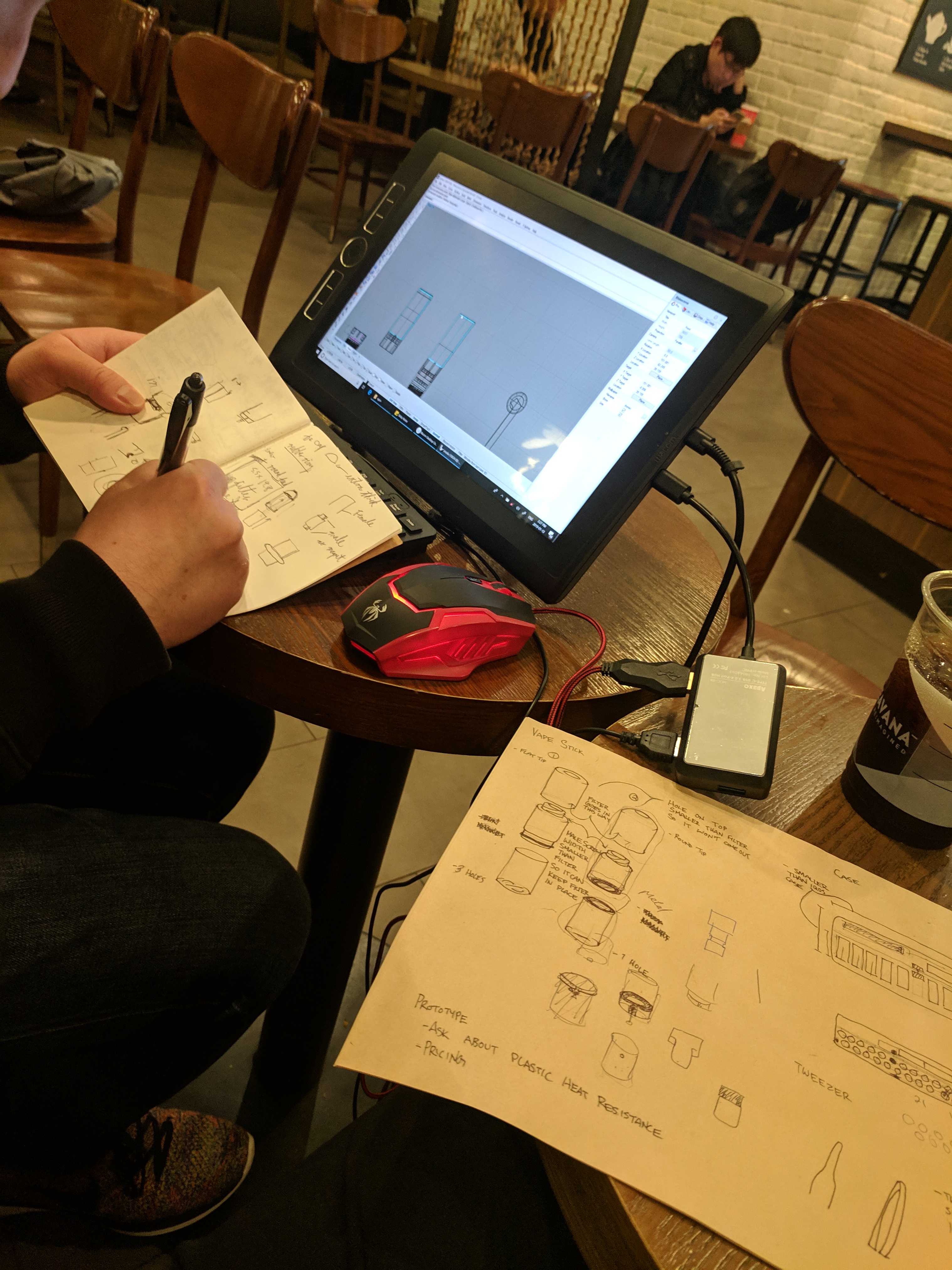

Step one was to get my hands on an IQOS device and take it apart. For this, I enlisted the help of Ronald from Devil Claw Jewellery. We measured the heating chamber, heatstick dimensions, and device tolerances — essential for designing a cartridge that could fit seamlessly.

Prototyping

The first step was to purchase an iQos and then disassemble it. I got help from a talented jewellery designer, Ronald from Devil Claw Jewellery, and made measurements of both the machine and the heatsticks. This helped us make initial assumptions for the design of a device that could fit properly.

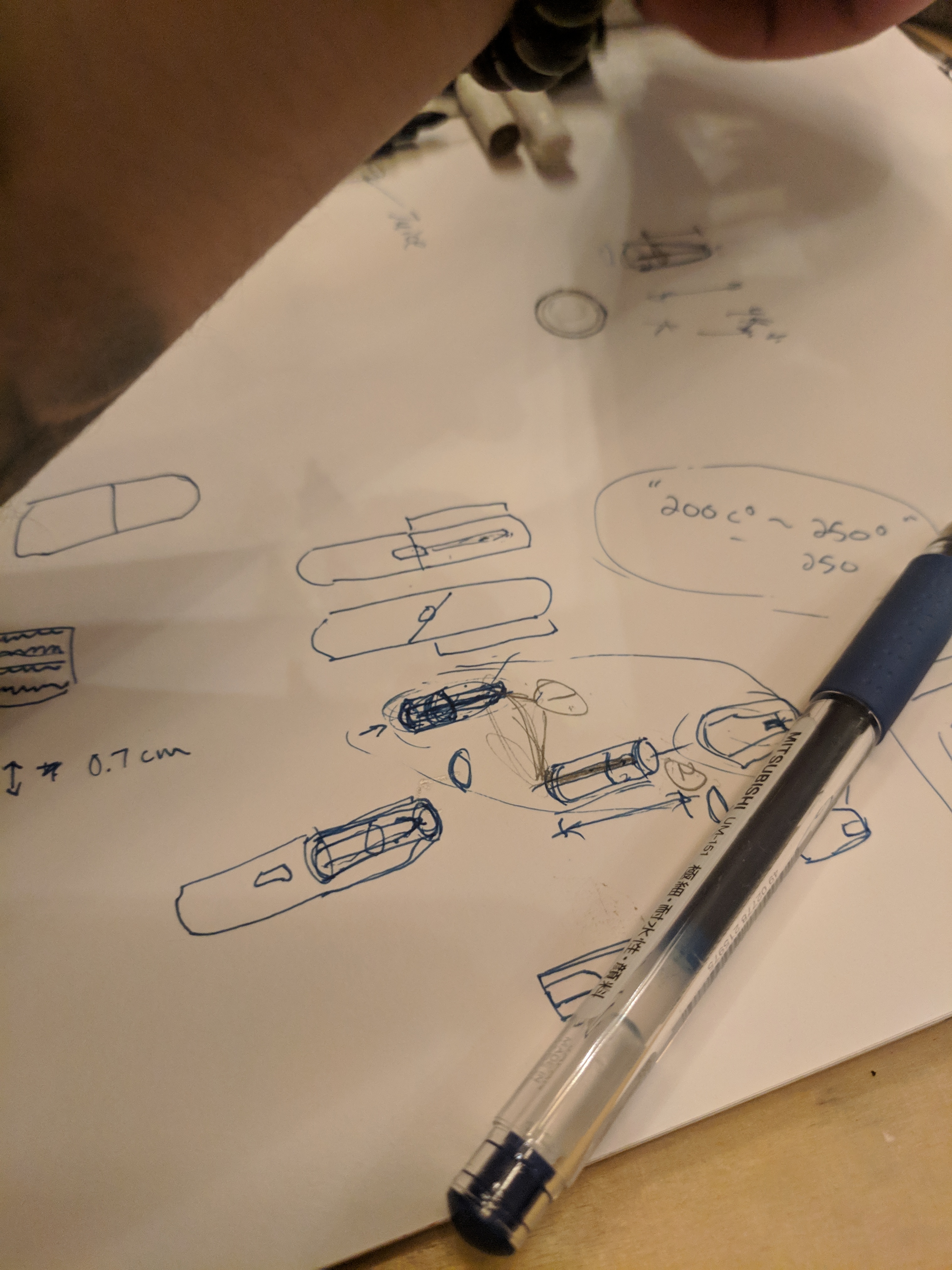

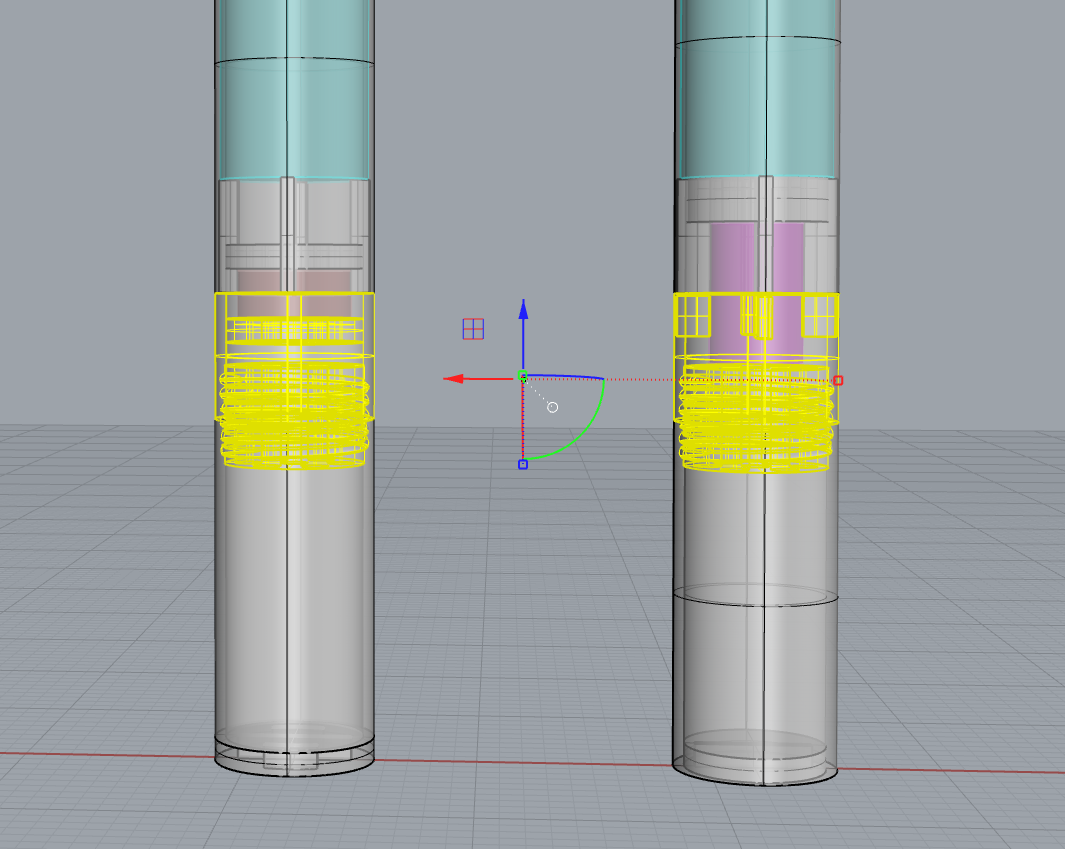

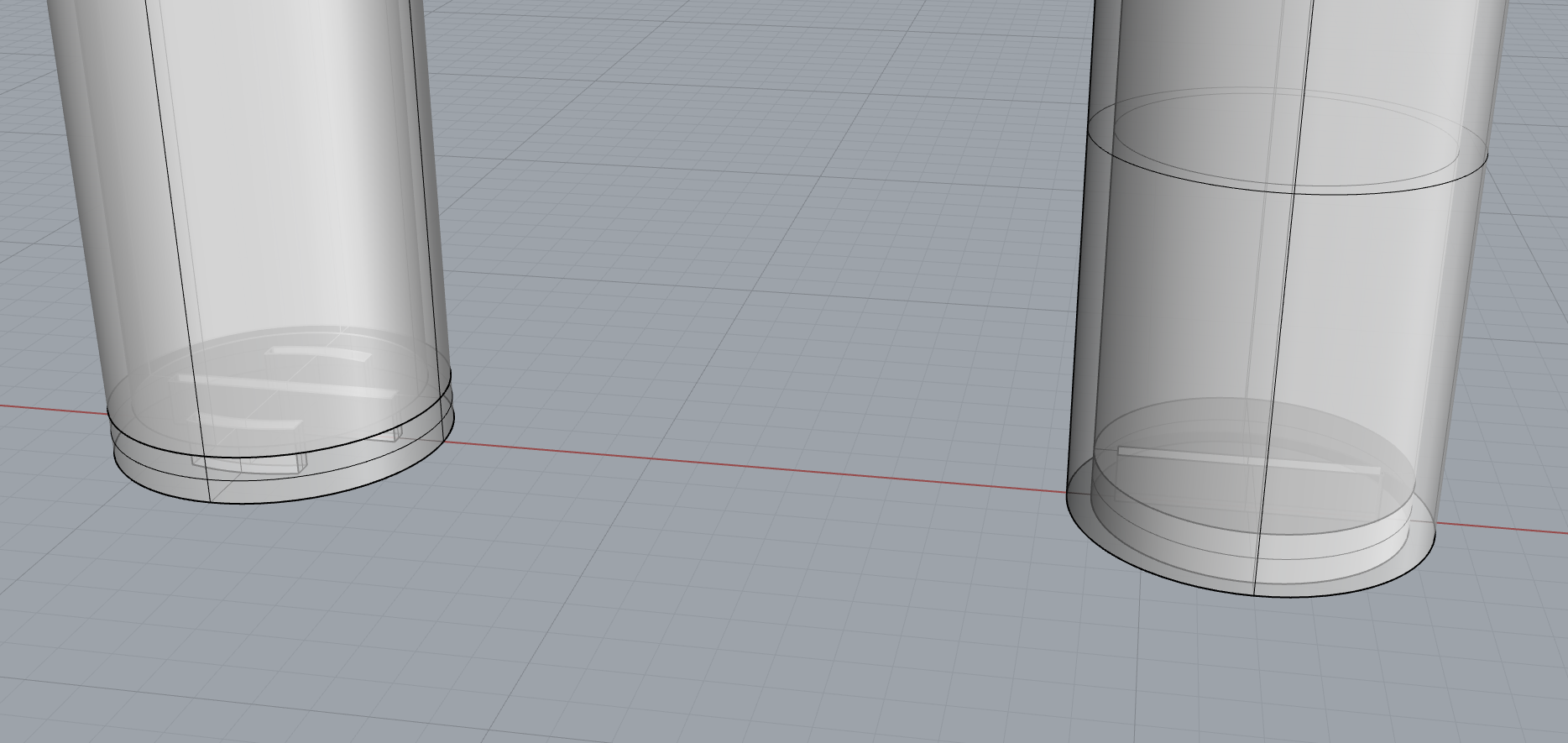

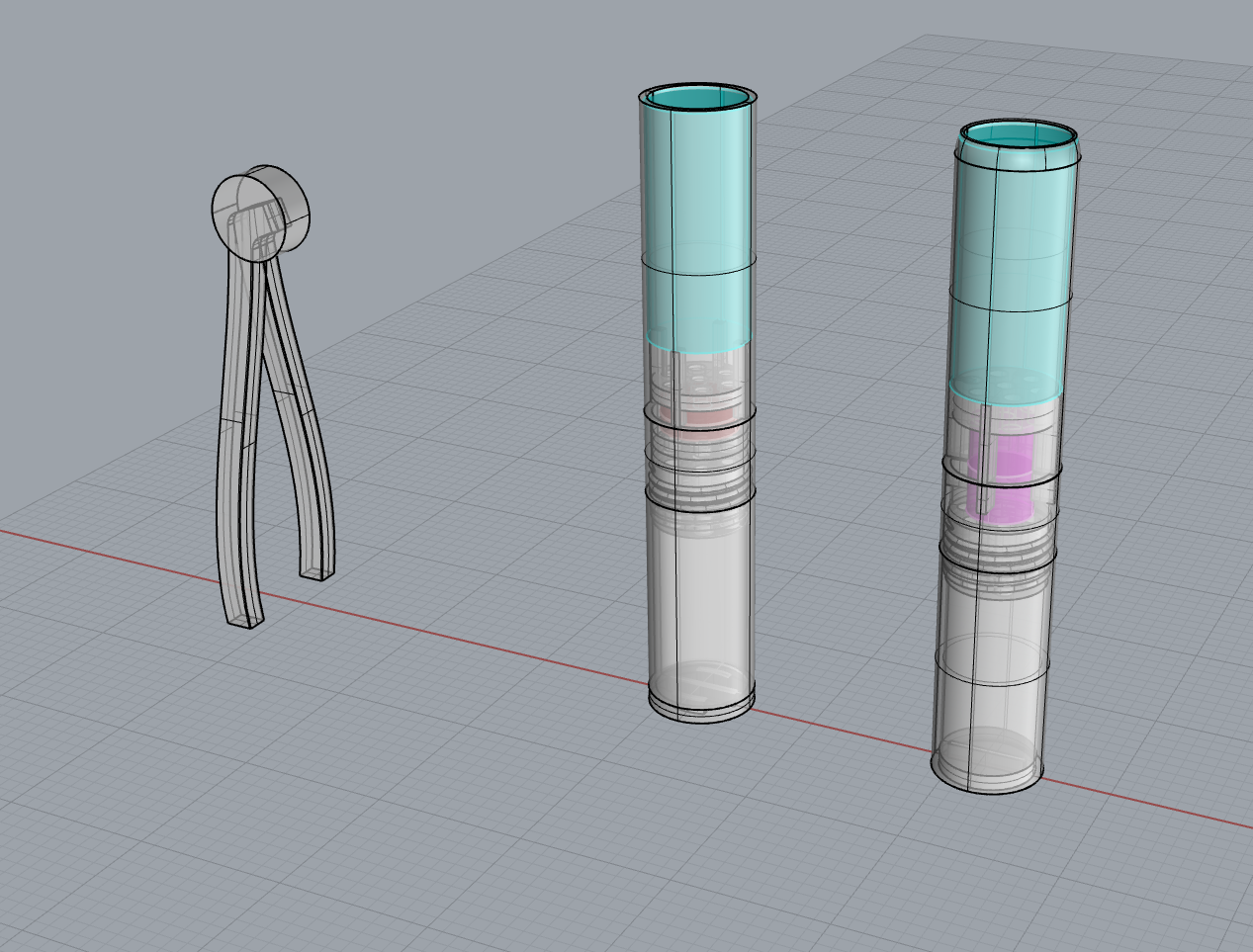

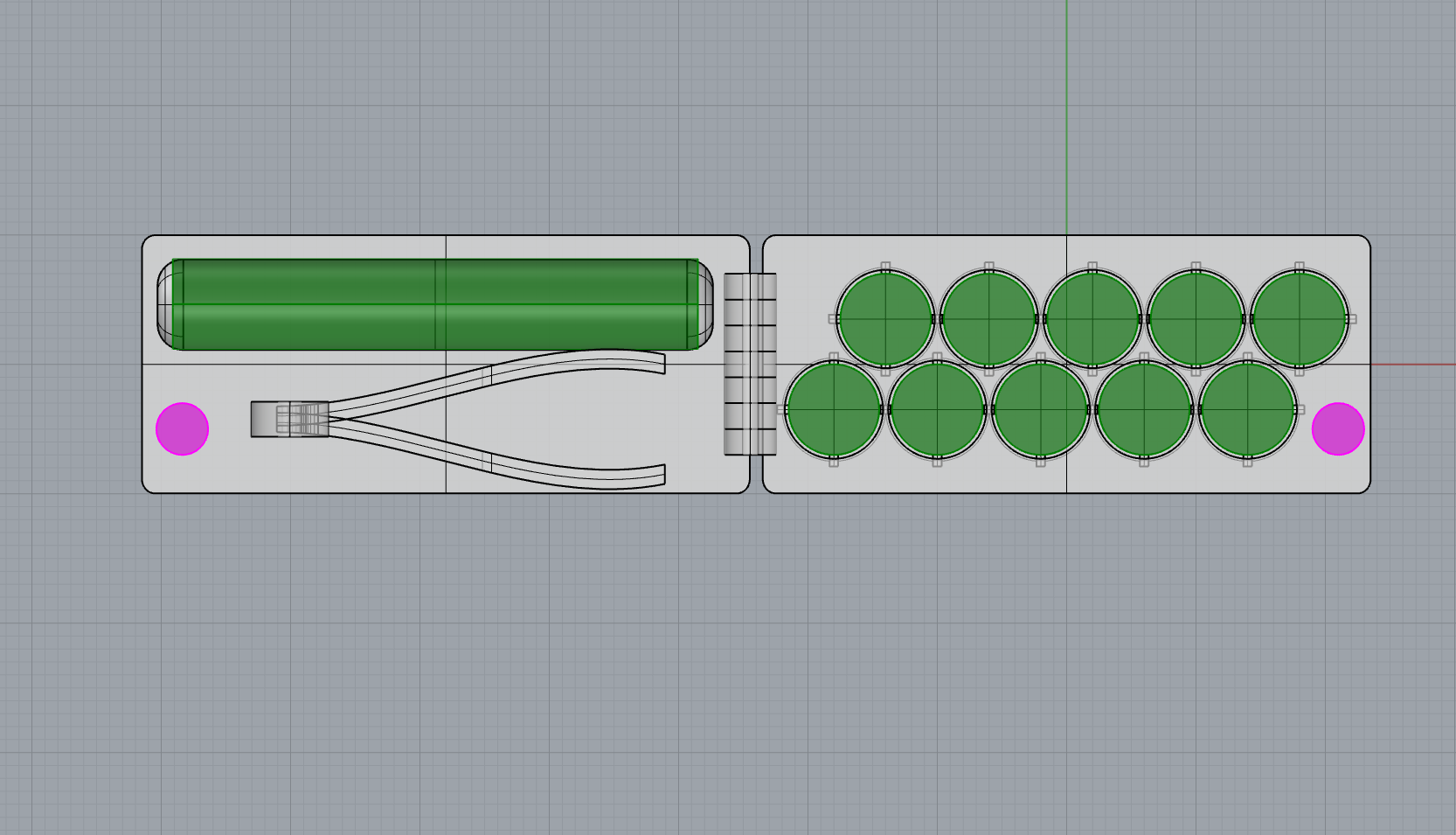

The cartridge design was split into two main sections:

Filter End – using a standard slim filter.

Tobacco Chamber – holding the loose leaf.

I explored two connection methods: a magnetic lock and a screw-tight design. The magnet idea was appealing for quick assembly, but high heat can weaken magnets over time, so I opted for the screw design.

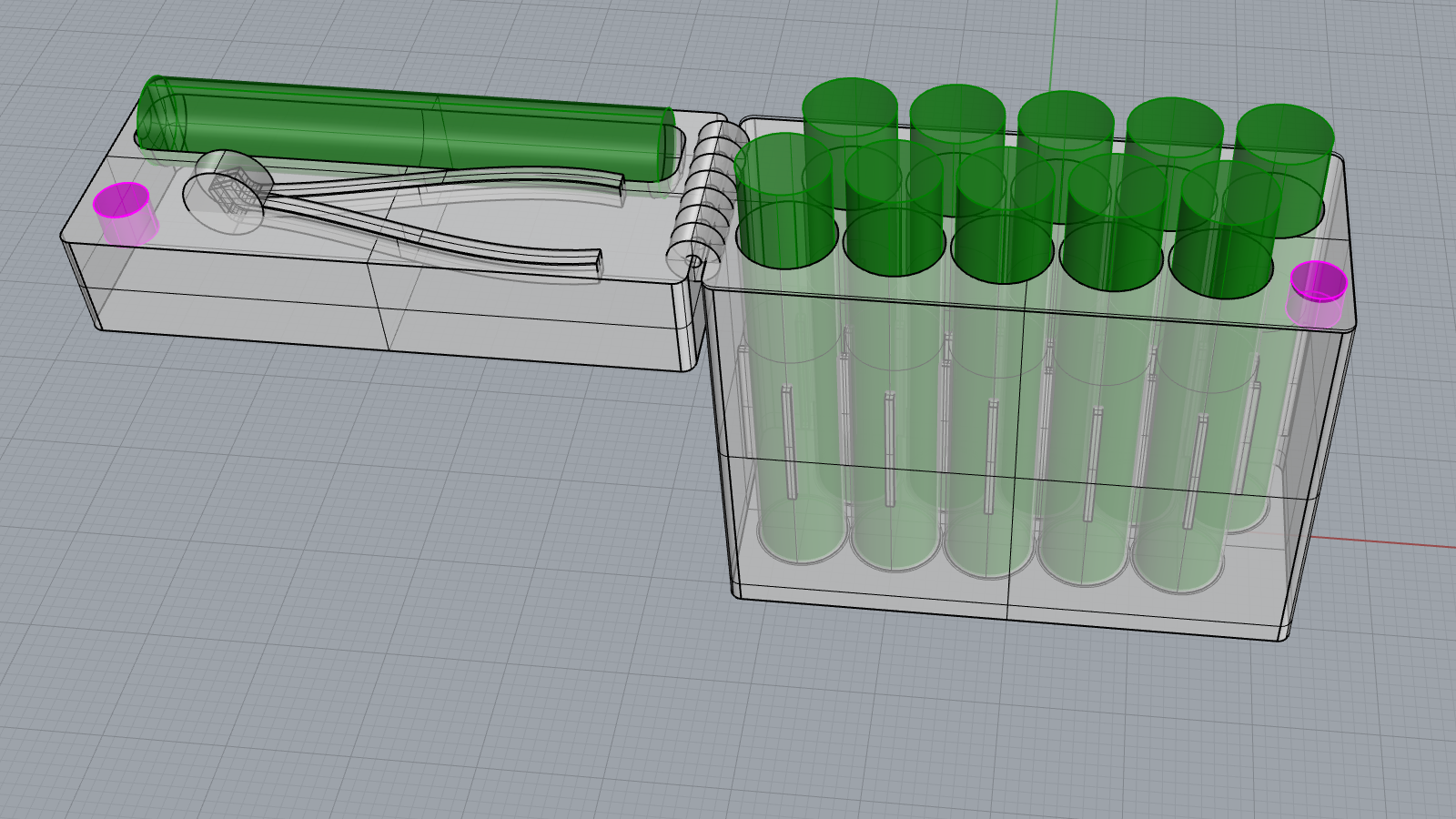

Additional components included:

A portable storage box for 10 pre-filled cartridges.

Tweezers for packing and removing tobacco.

Testing

In hindsight, I should have tested the idea before investing in modeling and 3D printing. My quick proof-of-concept involved using a bolt with roughly the same diameter as a heatstick, drilling a hole in it, filling it with loose tobacco, and loading it into my IQOS.

It worked… at first. I inhaled, tasted the tobacco, and thought I had nailed it — until I exhaled and realized there was no visible smoke. One of the core appeals of HTP (and even vaping) is exhaling vapor. It’s a physical sensation that gum and patches can’t replicate, and without it, the experience feels incomplete.

A bit of research revealed why: commercial heatsticks contain humectants like water and glycerin, which create aerosol and simulate smoke. Without adding this, the vapor simply isn’t there.

Reflection

By 2018, I decided to pause the project. Without the addition of glycerin (and perhaps other proprietary additives), Tobaqos couldn’t replicate the sensory experience that HTP users expect.

Was it the right call to stop? Possibly. But it was still a valuable exercise in product design, rapid prototyping, and learning the practical limitations of retrofitting existing tech. And who knows — maybe the idea will get revisited one day.

Currently, HTP has newer models where a metal chip is embedded into the heat sticks.